Oil Less Air Compressors: The Ideal Solution for Your Clean Air Needs

In industries where air purity is non-negotiable, oil-less air compressors stand out as the ideal solution. These compressors are designed to operate without oil in the air compression process, ensuring that the compressed air produced is entirely free from any oil contamination. Whether you're in the food, beverage, pharmaceutical, laboratory, or electronics industry, Specialty Gas offers a range of high-quality oil-less compressors that meet the strictest standards of cleanliness, efficiency and reliability.

Understanding Oil-Less Air Compressors

Oil-less air compressors differ from traditional oil-lubricated models in that they do not require oil to lubricate the moving parts within the compression chamber. Instead, they utilize advanced materials such as Teflon or other durable coatings to reduce friction and wear. This design eliminates the risk of oil contamination in the air stream, making them an excellent choice for industrial applications where pure air is essential.

Key Benefits of Oil-Less Air Compressors

Pure, Contaminant-Free Air

The absence of oil in the compression process ensures that the air is entirely free of oil contaminants, which is crucial for maintaining product integrity and safety in sensitive applications.

Low Maintenance

Without the need for oil changes, oil filter and air-oil separator replacements, the oil-less compressors are easier and less expensive to maintain. This translates to reduced downtime and lower operational costs over the long term.

Environmentally Conscious

Oil-less compressors contribute to a cleaner environment by eliminating the need for oil disposal and eliminating the risk of oil leaks.

Reliable Performance

Advanced materials and design ensure that oil-less compressors deliver consistent, reliable performance, with less wear on components, leading to a longer lifespan.

Applications of Oil-Less Air Compressors

Oil-less air compressors are essential in various industries where air quality cannot be compromised:

Food and Beverage Production

In the food and beverage industry, maintaining a contaminant-free environment is critical. Oil-less compressors ensure that no oil particles enter the production process, safeguarding product quality.

Pharmaceutical Manufacturing

Pharmaceuticals require the highest levels of cleanliness. Oil-less compressors provide the pure air needed to produce safe and effective medicines.

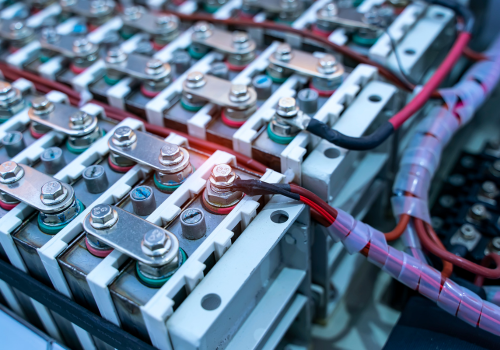

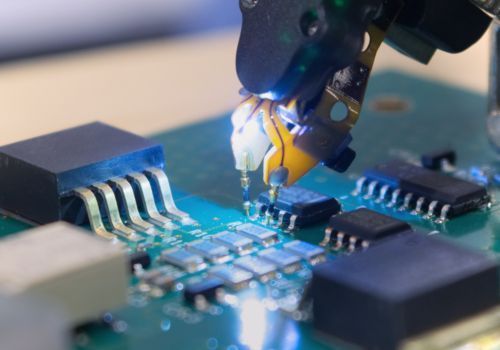

Electronics Manufacturing

The electronics industry demands clean air to prevent contamination of sensitive components. Oil-less compressors deliver the oil-free air necessary for these precision processes.

Medical and Dental Applications

In healthcare settings, oil-less compressors are used in equipment such as ventilators and dental tools, where air purity directly impacts patient safety.

Laboratory

Oil-less air compressors ensure a contaminant-free lab environment by preventing oil vapor contamination. They provide pure compressed air for sensitive instruments and experiments, essential for precise processes like gas chromatography and mass spectrometry.

Blood Testing

Laboratory blood analyzers and centrifuges rely on oil-free air to maintain precision and avoid contamination, ensuring accurate medical diagnostics.

Reverse Osmosis

In water filtration, oil-free air powers micro-bubble cleaning systems that improve membrane efficiency, ensuring optimal filtration performance.

Ozone Generation

Oil-free air is crucial for producing ozone, which is used in water and air purification processes. It ensures efficient oxygen conversion without hydrocarbon interference.

Wastewater Management

Oil-free compressors support aeration and filtration in wastewater treatment, preventing oil contamination that could disrupt biological processes.

Fishing Bait

Oil-free air is used to aerate bait tanks, maintaining oxygen levels for fish while ensuring a clean, oil-free aquatic environment.

Glass Frit and Sand Blasting

In high-temperature coatings and sandblasting applications, oil-free air prevents contamination, ensuring smooth coatings and precise surface treatments.

Why Choose Specialty Gas for Your Oil-Less Air Compressor Needs?

At Specialty Gas, we are committed to providing our customers with the best oil-less air compressors available. As an authorized distributor of Anest Iwata compressors, we offer products that combine cutting-edge technology with exceptional reliability.

A line drawing of a hand holding a person and stars.

Expert Guidance and Support

Our team of experts is here to help you choose the right oil-less compressor for your specific needs. With our deep industry knowledge, we can guide you through the selection process, ensuring that you get the best solution for your application.

A magnifying glass with a person in the middle of it.

Customer-Focused Service

We prioritize our customers' needs, offering personalized service from consultation through to after-sales support. Our goal is to ensure that you are completely satisfied with your purchase and that your operations run smoothly with our high-quality compressors.

A black and white icon of an arrow pointing up with stars.

Top-Tier Products

Partnering with Anest Iwata, a leader in oil-less air compressor technology, means that we provide products that are built to last and perform at the highest level. You can trust that our compressors will deliver the clean, reliable air your business requires.

Contact Us Today

Oil-less air compressors offer unparalleled benefits for industries where air purity is critical. By choosing Specialty Gas as your compressed air expert, you can rest assured that you are getting the best products and support available. Reach out to us today to discover the ideal oil-less air compressor for your business.

Interested in learning more about how oil-less air compressors can benefit your operations? Contact Specialty Gas today. Our knowledgeable team is ready to assist you in finding the perfect compressor solution for your clean air needs.