Essential Components of a Nitrogen Generation System

Let me walk you through the key components of a nitrogen generation system, and their roles in ensuring everything runs smoothly.

As someone who's spent years working with nitrogen generation systems, I’ve seen firsthand how important these systems are for many industries, as they provide a reliable and efficient source of nitrogen.

How Does a Nitrogen Generation System Work?

A nitrogen generation system pulls in air from the environment, filters out the oxygen, and produces nitrogen, which is then stored for use. The system comprises several key components, including the air compressor, filters, dryer, nitrogen generator, and storage tanks. If any of these components aren't maintained properly, the entire system can suffer.

1. The Air Compressor: The Heart of the System

The air compressor is central to the nitrogen generation process. In systems I’ve worked with, a 30-horsepower compressor is often used to maintain pressure between 115 and 125 PSI. This consistent pressure is essential for efficient nitrogen production. It’s important to regularly check the compressor for any warning lights that could signal an issue. Ignoring these can lead to performance problems.

2. Filtration: Ensuring Clean Air for Nitrogen Production

Filtration is crucial because it removes contaminants from the compressed air before it reaches the nitrogen generator. Filters must be maintained to prevent clogs that could impact nitrogen purity. The filters in the systems I’ve encountered often include an automatic drain to handle contaminants, but it’s essential to keep an eye on the system for any potential leaks or blockages.

3. The Air Dryer: Removing Moisture to Maintain Nitrogen Quality

The

air dryer removes moisture from the compressed air, which helps prevent corrosion and other damage to the system. It’s important to regularly empty the

oil-water separator to prevent water build-up. In some environments, this might need to be done more frequently.

4. Compressed Air Tanks: Storing Air Before Nitrogen Production

The

compressed air tank stores clean, dry air at around 115 PSI, ready for nitrogen production. It’s important to regularly check for any water accumulation in the tank, as this can indicate an issue with the air dryer or filtration system. Maintenance is key to avoiding any disruptions in nitrogen production.

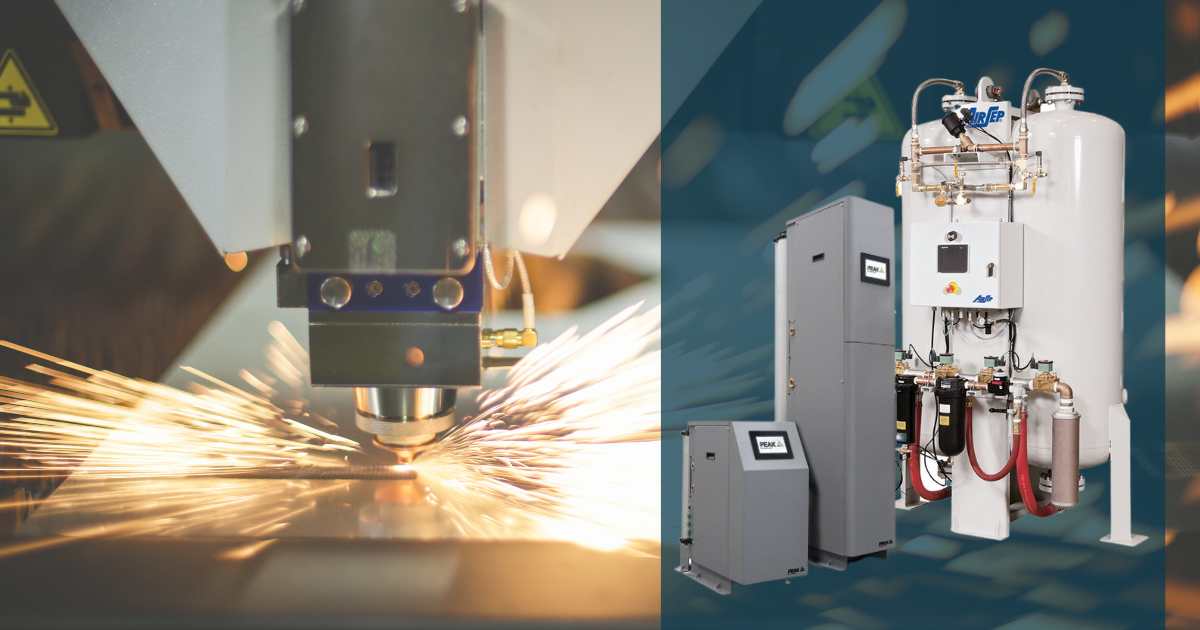

5. Nitrogen Generator: Producing High-Purity Nitrogen

The

nitrogen generator

separates nitrogen from oxygen, producing high-purity nitrogen with a purity level of 99.99%. To ensure the generator functions correctly, regular maintenance according to the manufacturer’s guidelines is essential. Skipping these steps can lead to reduced nitrogen purity, which can cause issues in industrial applications.

Once produced, nitrogen is stored in a

low-pressure tank before being boosted into a

high-pressure tank for storage. The pressure levels in these tanks are typically around 350 PSI. It’s important to monitor these levels regularly to ensure the system operates smoothly.

Maintenance and Troubleshooting for Long-Term Efficiency

Proper maintenance is key to ensuring a nitrogen generation system’s longevity. Following the manufacturer’s service guidelines, monitoring pressure levels, and addressing any warning signs promptly will keep the system running efficiently for years.

- Daily checks: Regularly empty the oil-water separator.

- Pressure checks: Ensure air and nitrogen pressures are within their designated ranges.

- Monitor for warnings:

Address any yellow or red lights immediately.

Conclusion: A Reliable Solution for Nitrogen Production

A nitrogen generation system is a significant investment, but with proper care and maintenance, it can provide reliable service for many years. By understanding the components and their functions, and by keeping up with regular maintenance, you can ensure your system operates efficiently and effectively.

For more information about these systems, check out our nitrogen generator page.

Share This Article With Your Network