Learn how to Boost Product Freshness with On-Site Nitrogen in Modified Atmosphere Packaging

Let's commence with the severe realities: according to the World Health Organization, nearly 10% of the global population falls ill due to consuming contaminated food, resulting in a staggering 420,000 annual fatalities. In the United States, approximately 40% of food ends up in landfills, a substantial portion of which is attributed to food spoilage, as revealed by the Harvard School of Engineering. Various factors, including bacteria, chemicals, heat, light, and surprisingly, oxygen, contribute significantly to this food spoilage problem.

Surprising Culprit: Oxygen's Role in Food Spoilage

The presence of oxygen might raise eyebrows, and you're not alone if you find it unexpected. Often Oxygen (O2) is perceived as a life-saving component, oxygen constitutes 21% of our atmosphere, alongside 78% nitrogen (N2) and 1% of other gases. When food is exposed to atmospheric air, it comes in contact with a 21% oxygen concentration, providing an ideal environment for microorganism growth and accelerating food spoilage. Food manufacturers and packagers are aware of these problems, and many have turned to Modified Atmosphere Packaging (MAP) machines to extend the shelf life of their products.

Modified Atmosphere Packaging (MAP): A Game-Changing Solution

In straightforward terms, Modified Atmosphere Packaging (MAP) involves altering the composition of gases used in food packaging compared to the atmospheric mix. This innovative process predominantly employs a gas mix high in Nitrogen, often reaching around 99%, thereby restricting the oxygen content to 1% or even lower. The global market for modified atmosphere packaging, projected to reach a staggering $25 billion USD in the next decade, has already established a significant presence with a current market size of $16 billion USD as reported by market researcher Fact.Mr in 2023. This growth, expected at a Compounded Annual Growth Rate (CAGR) of 4.5%, attests to the increasing recognition of MAP's pivotal role in food preservation.

Understanding Advantages and Disadvantages of MAP

The paramount advantage of Modified Atmosphere Packaging lies in its ability to extend the shelf/storage life of food products, enabling prolonged storage, and facilitating long-distance or remote shipping with minimal concerns regarding spoilage. Beyond this, MAP champions an organic approach to packaging by eliminating the need for chemicals traditionally used in food storage. Moreover, it acts as a guardian of physical attributes by preserving the colour, taste, texture, and overall quality of the product. However, like any technological innovation, MAP is not without its challenges. A nuanced understanding and skilled handling of the gases required for MAP pose hurdles. Additionally, there's an associated cost, primarily tied to the optional feature of Nitrogen flushing in packaging machines, along with the ongoing expense of acquiring the necessary gases. Despite these challenges, the undeniable benefits make MAP a transformative force in the space of food packaging and preservation.

Tailoring Gas Composition for Optimal Preservation

Within the realm of modified atmosphere packaging, three key gases take centre stage: Nitrogen (N2), Carbon Dioxide (CO2), and Oxygen (O2). Among these, Nitrogen emerges as the predominant player, constituting the majority of the gas mix used in packaging. Its odourless, tasteless, colourless, and non-toxic properties, coupled with its abundant presence in the atmosphere, render Nitrogen exceptionally well-suited for Modified Atmosphere Packaging. Yet, adhering to the principle that one size doesn't fit all, the gas composition varies based on the specific requirements of different food products. Delving into the details of this tailored approach, we've conducted an exhaustive exploration of scholarly articles and performed various gas purity tests in the food industry, culminating in a comprehensive table below. This table outlines the recommended purity levels for Nitrogen and other gases in Modified Atmosphere Packaging, recognizing that the optimal gas mix is contingent on the unique characteristics and preservation needs of each food item.

| Product | Recommended Nitrogen (N2) & other Gases Purity in MAP | An Estimated Shelf Life by maintaining the recommended Purity |

|---|---|---|

| Coffee | 99.5% N2 and 0.5% O2 | 18 Months |

| Vegetables | 98% N2 and 2% O2 | 3 Weeks |

| Roasted/Dried Food | 99% N2 and 1% O2 | 18 Months |

| Fruits | 97% N2 and 3% O2 | 4 Weeks |

| Bread | 20% N2 and 80% CO2 | 10 Weeks |

| Poultry Meat | 50% N2 and 50% CO2 | 2 Weeks |

| Cooked Meat | 75% N2 and 25% CO2 | 2 Months |

| Potato Chips | 97% N2 and 3% O2 | 6 Months |

| Pasta | 80% N2 and 20% CO2 | 3 Months |

| Wine | 98% N2 | 6 Months |

| Salad | 80% N2 and 20% CO2 | 3 Weeks |

| Lettuce | 97% N2 and 3% O2 | 3 Weeks |

When it comes to Modified Atmosphere Packaging (MAP), one cannot emphasize enough the importance of adhering to proper storage conditions in order to maximize the recommended shelf life of food products. In fact, the shelf life outlined in the table provided is contingent on maintaining specific storage conditions, including temperature, sunlight exposure, humidity levels, and more, as specified by the manufacturer's guidelines. It is through this meticulous attention to detail that the true potential of MAP is harnessed, allowing for optimal food preservation.

Temperature control plays a significant role in the effectiveness of MAP. Different food products have different temperature requirements for storage. For example, perishable items such as fresh meat and produce may require lower temperatures to slow down the growth of spoilage microorganisms, while other packaged foods may require slightly higher temperatures to maintain their quality over an extended period. By closely monitoring and maintaining the recommended temperature range, food manufacturers can ensure that the desired atmosphere within the packaging is achieved and maintained throughout the product's shelf life.

Sunlight exposure is another critical factor to consider when utilizing MAP. Light, especially ultraviolet (UV) radiation, can have detrimental effects on food quality and accelerate the degradation process. Packaging materials with UV-blocking properties can help mitigate the harmful effects of sunlight exposure and prolong the freshness of the packaged food. Additionally, storing MAP-packaged products in dark or opaque containers further reduces the risk of light-induced deterioration, ensuring that the food maintains its optimal quality for an extended period.

Humidity control is equally important when it comes to MAP. Excessive moisture can lead to the growth of mold and bacteria, ultimately leading to spoilage. On the other hand, extremely dry conditions can cause the food to become dehydrated and lose its original texture and flavor. Therefore, maintaining the appropriate humidity level within the packaging is crucial for preserving the quality and freshness of the food. Through the use of moisture-absorbing or moisture-releasing agents within the packaging, food manufacturers can effectively regulate the humidity and create an ideal environment for the product.

Furthermore, it is worth noting that the manufacturer's guidelines are the key to unlocking the full potential of MAP. These guidelines are developed based on extensive research and testing to ensure that the desired gas mixture and packaging materials are utilized correctly. Each food product may have specific requirements, and following the manufacturer's recommendations guarantees that the optimal atmosphere is achieved and maintained. Adhering to these guidelines also plays a significant role in food safety, as improper use of MAP can potentially result in the growth of harmful bacteria or compromise the overall quality of the product.

To summarize, Modified Atmosphere Packaging offers immense benefits in terms of extending the shelf life of food products by virtue of Nitrogen and other gases compositions. However, realizing these benefits requires a steadfast commitment to proper storage conditions. By diligently monitoring and controlling factors such as temperature, sunlight exposure, humidity levels, and following the manufacturer's guidelines, food manufacturers can harness the full potential of MAP and ensure the preservation of product quality, freshness, and safety.

Nitrogen Flushing in MAP: Addressing Critical Needs

The data in the table above underscores the prevalence of Nitrogen gas flushing in the Modified Atmosphere Packaging (MAP) industry. When it comes to meeting the Nitrogen needs for this critical process, two primary avenues emerge: external delivery to food manufacturing facilities through cylinders, dewars, and storage tanks, or in-house production facilitated by a Nitrogen Generator. While food manufacturing operations often run continuously, the variability in demand for different food products underscores the need for adaptable Nitrogen supplies to ensure seamless packaging.

Adaptable Nitrogen Supplies: A Necessity for Seamless Packaging

In facilities where production aligns with demand, the reliance on delivered Nitrogen in gas form demands meticulous supply chain coordination. Interruptions or inadequacies in this coordination can grind production to a halt, resulting in significant losses. On the contrary, opting for on-site Nitrogen Generation via a Nitrogen Generator eliminates these supply chain and coordination challenges. With an on-site generation system, the food manufacturer is not dependent on external entities for Nitrogen gas delivery, ensuring a continuous and reliable supply.

In-House Nitrogen Generation: On Demand Gas Availability

For those grappling with the inconsistency of Nitrogen demand and relying on Dewars for MAP Nitrogen supply, a distinct set of challenges emerges. The sub-zero temperatures of Liquid Nitrogen within Dewars can lead to the freezing of Nitrogen lines, causing operational disruptions. To avoid these operational hiccups, installing Nitrogen Generators emerges as the optimal solution. Nitrogen Generators provide on-demand gas, eliminating concerns about frozen lines and offering a seamless and efficient means of fulfilling Nitrogen needs precisely when required.

In-House Nitrogen Generation: A Strategic Cost-Saving Approach

In the current landscape marked by a surge in food prices due to inflation, individuals are struggling with the challenge of managing their grocery bills. In this scenario, the adoption of in-house Nitrogen Generation Systems within food facilities emerges as a powerful strategy to ease overhead costs for food plants. The conventional method of procuring delivered Nitrogen (N2) for Modified Atmosphere Packaging (MAP) incurs a significant expense of around 80 cents per m3. In stark contrast, the in-house production of Nitrogen slashes this cost dramatically, at a mere 5 cents per m3. This not only translates to substantial immediate savings but also insulates food facilities from the risk of inflation that has seen delivered N2 prices spike by 50% over the last three years. Drawing insights from recent studies conducted at two food facilities in Ontario, Canada—Customer#1 (a Vegetable Packaging Plant) and Customer#2 (a Coffee Packaging Plant)—the potential for savings is compelling. Projections indicate that Customer#1 stands to save $660,000, while Customer#2 is poised to realize savings totaling $1.5 million over the next decade by transitioning to in-house Nitrogen gas production facilitated by Nitrogen Generators.

The Return on Investment (ROI) for a Nitrogen Generator tailored for Modified Atmosphere Packaging typically materializes within a remarkably short timeframe, ranging between 10 to 12 months. Moreover, the expected operational life of a well-maintained robust generator like Peak Gas i-Flow extends to 20 years, ensuring a prolonged period of cost-effectiveness. An often overlooked yet crucial factor of in-house Nitrogen production is its positive impact on the environment. By eliminating the need for trucks to deliver gas, the carbon footprint associated with transportation is eliminated, aligning with sustainable practices and contributing to a greener future.

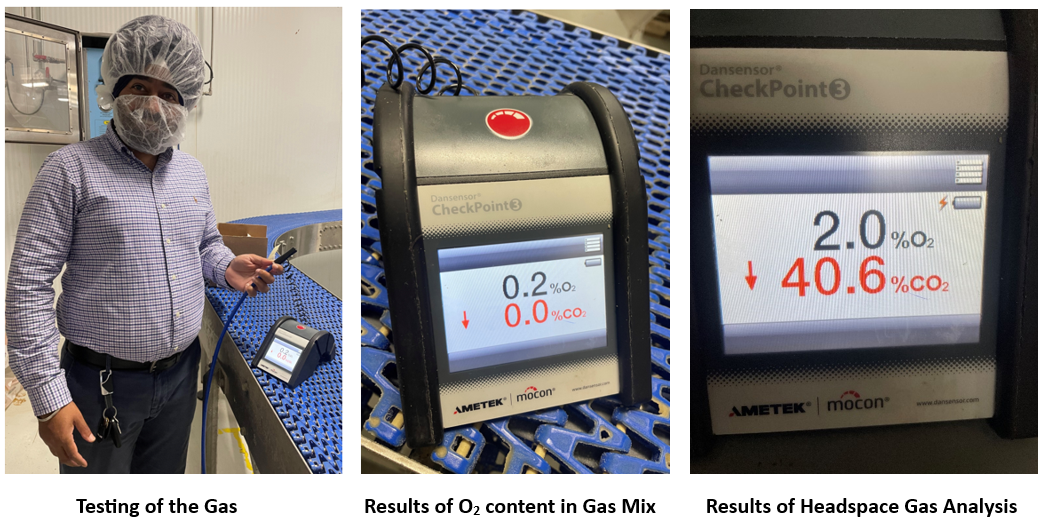

Monitoring and Ensuring Purity for Quality Assurance

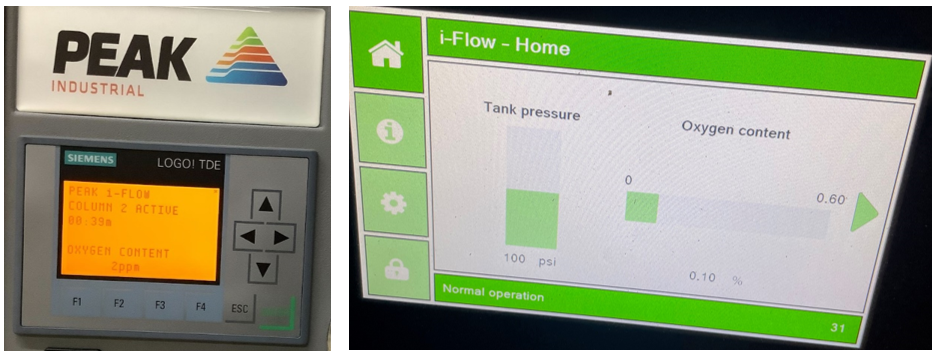

Recognizing the pivotal role that high Nitrogen content and low Oxygen content play in food packaging, it becomes imperative to adhere to the adage that you can't improve what you don't measure. Unfortunately, the significance of regularly testing the purity of Nitrogen used in food packaging is often overlooked in many plants. This oversight can have severe repercussions, leading to compromised freshness, diminished shelf life, and even potential spoilage. In an industry where quality and safety are non-negotiable, neglecting this critical aspect is a risk we cannot afford to take. The Peak i-Flow Nitrogen Generators set themselves apart by incorporating an inbuilt purity sensor as a standard feature, constantly displayed on the screen. The display provides real-time information in either percentage purity or parts per million (PPM), catering to specific requirements. This data can also be remotely monitored with analytics along with optional interfaces for live status tracking and BMS integration.

Proactive Purity Monitoring for Delivered Nitrogen

For food plants relying on delivered Nitrogen gas, a proactive approach involves consistent monitoring of purity using dedicated meters or sensors. Regularly assessing the purity of Nitrogen ensures that products consistently meet the highest quality standards.

This not only fosters customer satisfaction but also contributes to the reduction of food waste and the preservation of the environment. By taking this proactive step, we can reinforce the integrity of products, enhance food safety, and extend the shelf life of packaged goods.

Canadian Food Inspection Agency (CFIA) has not only published the importance of modified atmosphere packaging to increase the shelf life of food products but also mentioned the significance of performing the regular

headspace gas analysis in the testing for the integrity of the packaging.

Adapting to Changing Demands with Scalable Solutions

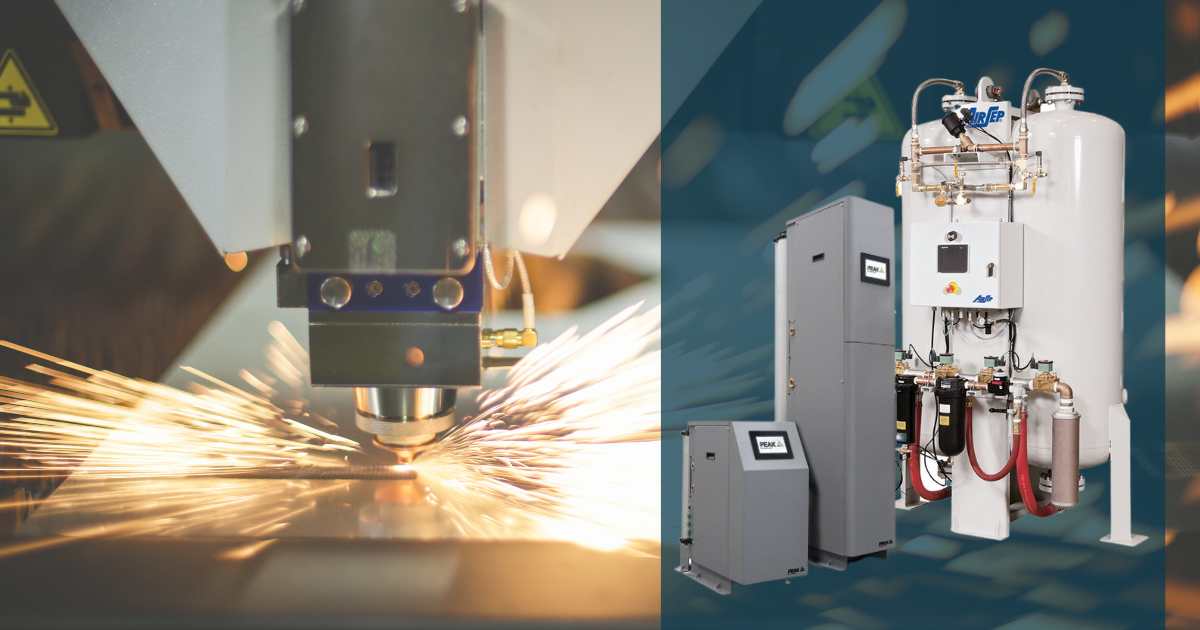

Addressing the concern of adapting to the escalating demand for Nitrogen when integrating new or multiple Modified Atmosphere Packaging machines becomes paramount. Fortunately, reputable Nitrogen Generators such as the PeakGas i-Flow Nitrogen Generator are equipped with scalable and expandable features, rendering them future-proof solutions. This means the flexibility to incorporate additional Peak Carbon Molecular Sieve (CMS) banks post-initial installation. These added modules serve to augment maximum flow rates while upholding specified purity levels, ensuring seamless adaptation to evolving requirements. Visualized through the accompanying image, this modular approach allows for the incorporation of extra modules at a later date, presenting a dynamic solution capable of growing alongside the demands of the food packaging facility.

Nitrogen as a Preventive Measure Against Contamination

The COVID-19 pandemic has underscored the terrifying nature of viruses and bacteria, with a heightened awareness of airborne pathogens present in the ambient air. What may be less evident is the potential for airborne bacteria in a compressed air system, where the concentration is significantly amplified compared to ambient air. Typically, the concentration is seven times more severe when the system pressure is at 7 barg. Therefore, utilizing regular compressed air for food packaging not only exposes products to spoilage risks but also poses health hazards. In contrast, the use of Nitrogen in Modified Atmosphere Packaging serves as a preventive measure against bacterial growth. Moreover, Nitrogen produced through the Pressure Swing Adsorption (PSA) technique yields bone-dry Nitrogen with a dew point of -70 degrees Celsius. This dry environment impedes bacterial growth as they do not attain the requisite humidity levels for proliferation.

Enhancing Safety with Sterile Filtration

While employing Nitrogen as a protective measure, it's advisable to incorporate a sterile filter when applications have zero tolerance for contamination, the addition of a sterile, compressed gas filter assembly will ensure you have a risk mitigation strategy in place. Ultrafilter’s Stainless-Steel P-EG housing, with its non-shedding P-SRF 0.2µ steam sterilizable filter element, diminishes the impact of an unwanted event to further enhance the safety and hygiene of the food packaging process.

In Conclusion: On-Site Nitrogen Generation as a Multifaceted Solution

In conclusion, the adoption of on-site Nitrogen generation for Modified Atmosphere Packaging (MAP) emerges as a strategic and multifaceted solution to extend the shelf life of food products, tackle industry challenges, and prioritize quality assurance. This approach offers substantial benefits in terms of cost savings, environmental sustainability, and the flexibility to meet evolving demands. By utilizing on-site Nitrogen generation, food manufacturers can ensure freshness, reduce waste, and demonstrate a commitment to both customer satisfaction and environmental responsibility. With the use of cutting-edge technology and scalable solutions like Peak i-Flow Nitrogen Generators, companies can optimize their packaging processes, improve product quality, and enhance their overall competitiveness in the market. By leveraging MAP technology, food manufacturers can create a controlled atmosphere that helps maintain the desired gas mixture, such as reducing Oxygen levels and enhancing Nitrogen levels, thereby effectively extending the shelf life of perishable products like fresh fruit, nuts, and produce. This not only reduces spoilage and food waste but also enhances food safety and quality control measures. Moreover, on-site Nitrogen generation eliminates the need for frequent Nitrogen deliveries and reduces reliance on external suppliers, which translates to significant cost savings. Additionally, this approach eliminates the carbon footprint associated with transportation and storage of nitrogen gas cylinders, contributing to a more sustainable and environmentally friendly packaging process.

By implementing on-site Nitrogen generation systems, food manufacturers gain the flexibility to adjust nitrogen levels and tailor the packaging atmosphere according to the specific needs of different products, ensuring optimal freshness and quality. This versatility allows companies to adapt to shifting market demands and deliver products with extended shelf life, meeting the expectations of both retailers and consumers. The adoption of on-site Nitrogen generation for MAP is no longer just a strategic move; it is a commitment to excellence in food packaging, offering a comprehensive solution that addresses key industry challenges while maximizing product quality, minimizing waste, and demonstrating environmental responsibility.

References:

World Health Organization - Food Safety

The Grapevine Magazine - Article

Compressed Air Best Practices - Article

Government of Canada - Inspections: Shelf Studies

Government of Canada - Inspections: Preventive Controls

Book: Principles and Application of Modified Atmosphere Packaging of Foods – Second Edition – Edited by B.A. Blakistone.

Share This Article With Your Network